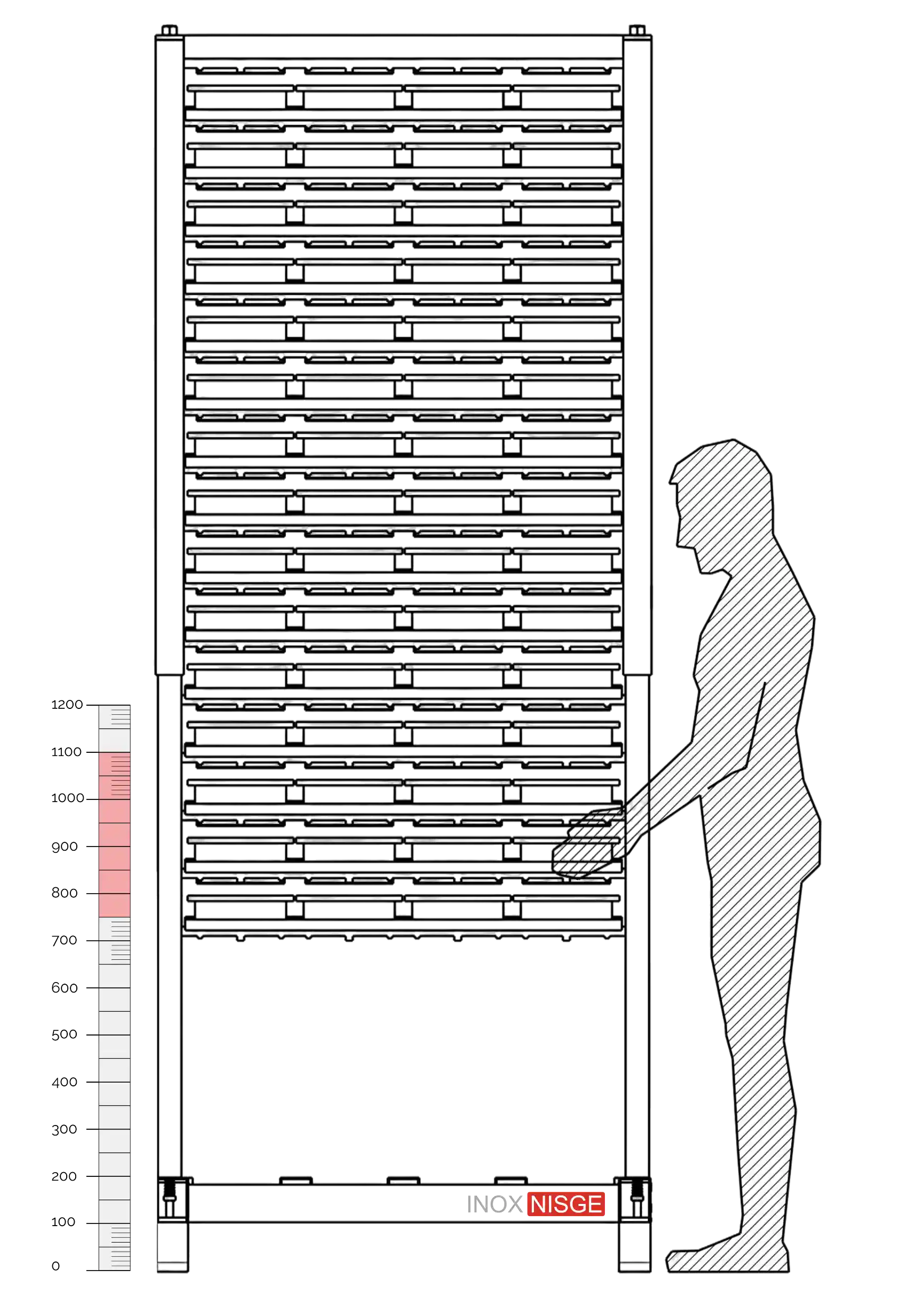

The innovative design of the INOXNISGE multi-mould system represents a significant advancement in operational ergonomics for industrial manual loading and unloading processes. This system is specifically engineered to allow operators to handle moulds within the optimal ergonomic height range (between 750 and 1100mm), conforming to international recommendations based on the weight being manipulated.The process utilises our specialised geared motor trolley that precisely controls the opening and closing of the multi-mould cage.

The operator, using a convenient pedal system, can manoeuvre the structure to position each level of moulds at the ideal height for safe handling. When a level of moulds reaches the ergonomic zone, the operator can easily extract them by sliding them along their integrated rails, transferring them to the destination platform or table for the next step in the production process. This operation is performed sequentially for all levels of the multi-mould structure.

During the unloading phase, the extracted moulds continue their journey through the production line while the multi-mould system continues adjusting to present the next level. Upon reaching the bottom level, using a geared motor rotation selector, the closing option is activated, allowing the upper levels to progressively descend into the ergonomic zone for sequential emptying.

Once the complete unloading is finished, the multi-mould cage remains fully closed and compact, optimising space and ready to begin the reverse loading process with new moulds containing raw food products for cooking.

The loading process begins with the upper level, initially positioned in the ergonomic zone. As each level is fully loaded, the geared motor system progressively opens the cage to present the next empty level, continuing until the loading of the final bottom level is complete.

Finally, the multi-mould closure is activated according to pre-established parameters that guarantee the precise positioning of each lid relative to the mould, ensuring optimal conditions for the subsequent cooking process of the product.

The multi-mould system incorporates a sophisticated pulley mechanism for transmitting vertical movement from the gearbox motor, optimising the opening and closing of the machine. This configuration ensures smooth and precise operation, reducing mechanical stress and extending the equipment's service life whilst maintaining energy efficiency during repetitive loading and unloading operations in demanding industrial environments.

The various levels of the multi-mould system interconnect through an advanced link chain system, engineered to maintain consistent spacing between platforms whilst allowing flexible height customisation according to each client's particular specifications. This adaptability ensures that the system can be optimally configured for different products and specific industrial processes, maximising production efficiency across diverse applications.

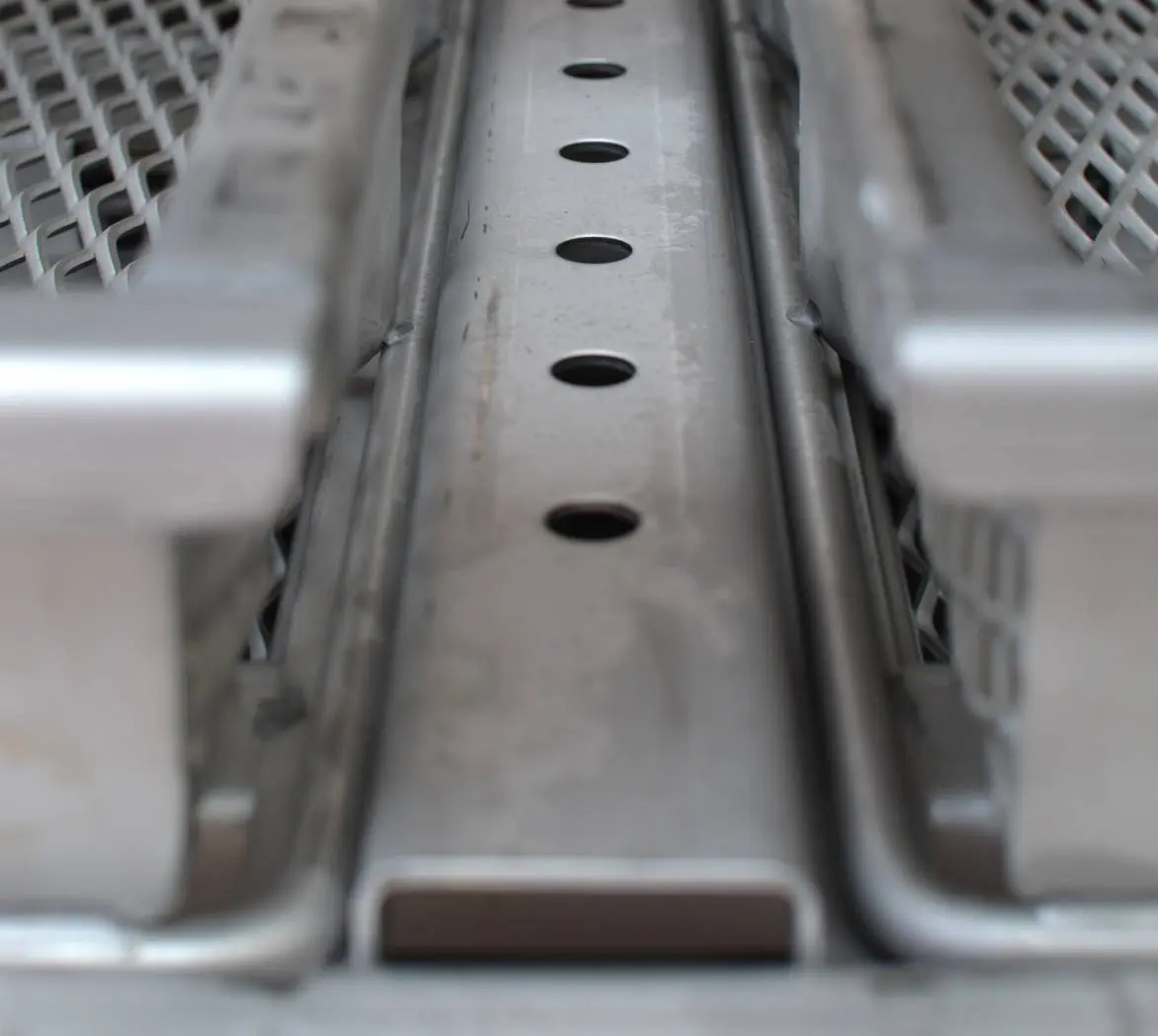

The perforated omega-profile supports installed to hold the covers for each level serve a dual essential function: they provide the necessary mechanical strength whilst facilitating air flow through the profile channel and via the multiple strategically distributed holes along the entire support structure. This innovative design allows hot air and/or smoke during cooking and/or smoking processes to effectively reach the innermost areas of the moulds, even when the cage is completely closed and compacted.

Contact Our Experts to Custom-Engineer Your Moulds or Multimoulds

contact us